Unitech Machinery’s CAD paint finishing systems are engineered to turn complex requirements into precise, high-performance solutions. With advanced 3D modelling and over 50 years of manufacturing expertise, we design surface finishing systems tailored to your space, workflow, and technical objectives.

Key Takeaways

- CAD paint finishing systems from Unitech Machinery are designed around your facility and process.

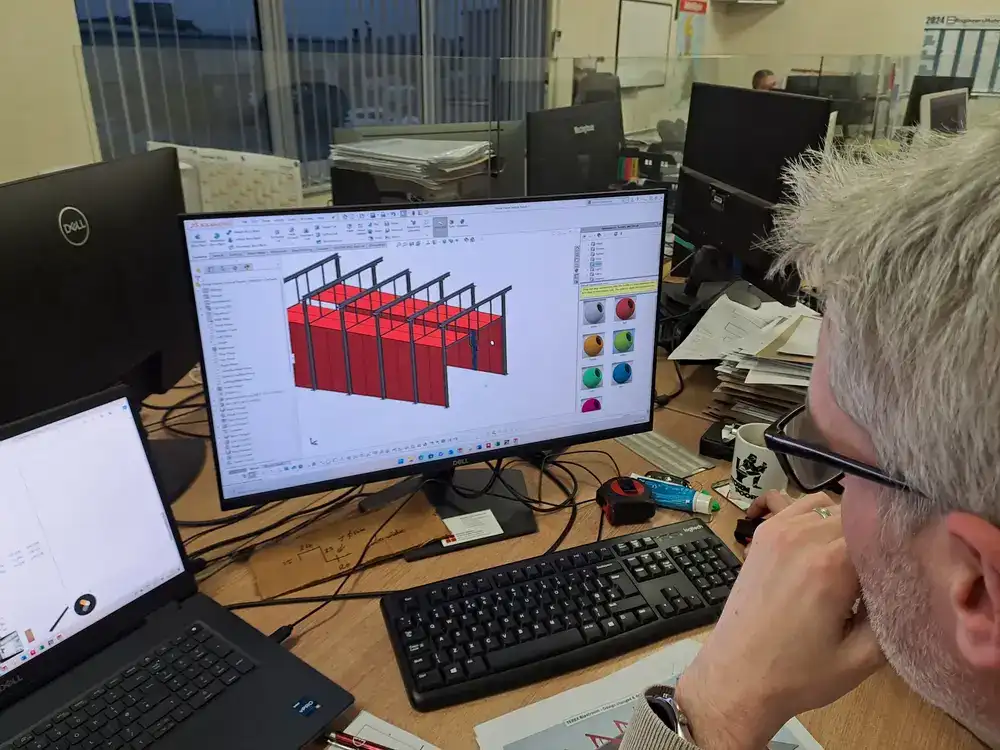

- Our 3D modelling service helps visualise complex layouts before installation.

- All design and manufacture are handled in-house at our UK facility.

- Our systems integrate seamlessly with automation, safety, and energy-saving controls.

- Trusted by brands across the automotive, aerospace, and commercial sectors.

Precision Design Using CAD for Paint Finishing Systems

Every spray booth, oven, or conveyor we design starts with detailed CAD modelling. This enables us to:

- Tailor the system to your facility’s unique dimensions

- Optimise airflow, ducting, and extraction placement

- Identify and eliminate layout clashes before installation

- Integrate safety, access, and maintenance zones

- Collaborate effectively with your internal team and contractors

Our engineering process ensures your CAD paint finishing system fits seamlessly into both new builds and retrofit environments.

3D Visualisation That Brings Your Facility to Life

Using full 3D renders, we help you visualise how your system will operate—before fabrication begins. Whether you’re planning a small booth or a multi-zone line, our designs help you:

- Sign off layout and functionality with confidence

- Coordinate with third-party suppliers more effectively

- Make layout changes without costly rework

This is especially useful for complex installations like fully integrated finishing lines or large-scale workflows.

Engineered in the UK, Built for Reliability

All systems are designed and manufactured in our Burntwood facility. This integrated approach allows our engineering team to collaborate closely with production—reducing lead times, avoiding communication gaps, and ensuring design intent is delivered exactly as specified.

We’re not just drawing systems—we’re building them.

Real Results from CAD-Engineered Projects

From aerospace and rail to automotive and commercial vehicles, Unitech Machinery has successfully delivered CAD-engineered paint finishing systems across the UK and internationally.

In one recent project, we developed a fully automated facility incorporating cleaning zones, flash-off areas, and curing ovens—all visualised via CAD before a single panel was installed.

➡️ Read the Automated Facility Case Study

Designed Around Your Workflow

We don’t force your process into a standard layout. Instead, we build CAD paint finishing systems that support:

- Efficient operator access and movement

- Safe maintenance and servicing clearances

- Streamlined material flow from prep to cure

- Compliance with safety, fire, and LEV requirements

If you’re planning a dry filter spray booth, our CAD service ensures it integrates perfectly into your facility, right down to the ductwork and lighting.

Talk to Our Design Team

Let’s explore what’s possible with CAD-engineered precision and over five decades of experience.

👉 Contact Unitech Machinery

📞 Call us on 01543 685565

Frequently Asked Questions: CAD Paint Finishing Systems

1. What software do you use for CAD and 3D modelling?

We use industry-standard CAD platforms capable of delivering 2D drawings and immersive 3D renders. This allows for clear approval and coordination at every project stage.

2. Can you provide visual designs before project sign-off?

Yes. We offer full CAD and 3D layout approvals before manufacture begins—allowing for design revisions, utility planning, and client walkthroughs.

3. Are your CAD designs suitable for retrofitting into old factories?

Absolutely. We frequently work in space-constrained or non-standard environments. Our CAD models are adapted to make best use of existing infrastructure.

4. How do your designs support energy efficiency?

During the CAD phase, we plan for optimal airflow, heat recirculation, LED positioning, and standby energy modes—helping reduce operational costs and carbon output.

5. Can you model full facilities including ovens and extraction?

Yes. We regularly model full systems with multiple zones, curing ovens, flash-off areas, and LEV extraction systems—all built around your production needs.