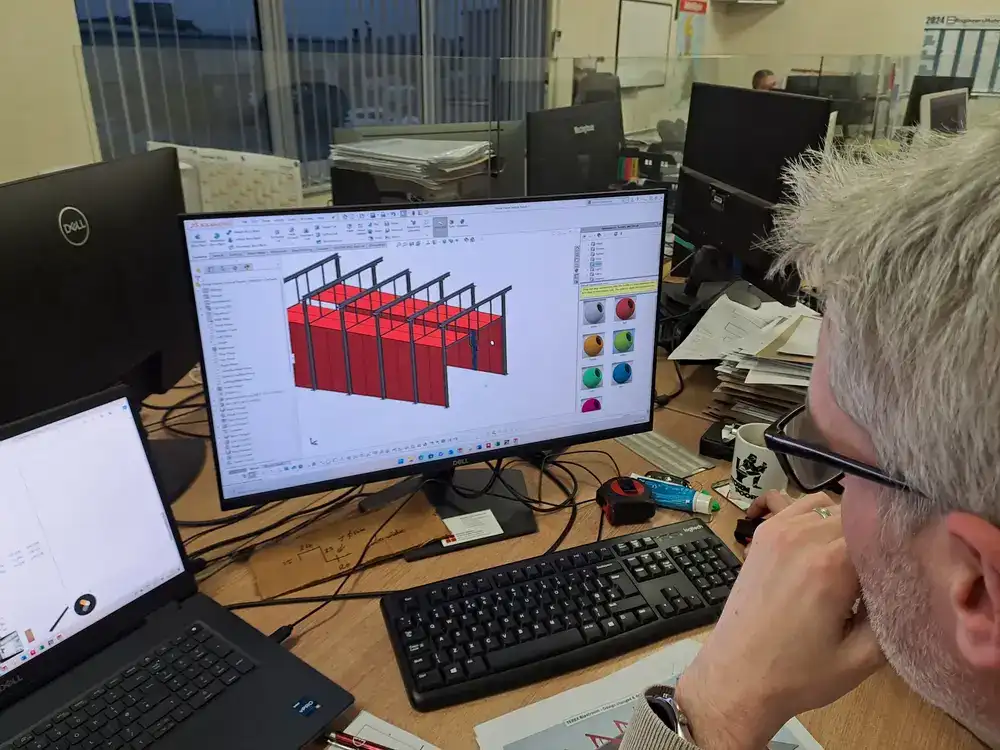

Beyond visualisation, 3D modelling acts as a powerful risk management tool. It helps pinpoint potential production bottlenecks and spatial challenges in advance, ensuring that layouts are optimised for efficiency. By simulating the entire production process, Unitech enables its clients to make informed decisions, streamline planning, and avoid costly modifications later in the build. This proactive approach not only reduces project risk, but also accelerates delivery timelines and keeps budgets on track.

Clients across the UK report significant time and cost savings as a result of this detailed approach. For manufacturers looking to modernise or expand their operations, Unitech’s 3D design expertise provides the confidence to proceed, knowing that every element has been engineered for efficiency.

Engineered Conveyorised Systems: Automating for Consistency and Output

As manufacturers look for ways to boost output and ensure quality, demand for conveyorised finishing lines and automated paint finishing continues to rise. Unitech’s conveyorised systems are designed from the ground up to suit each client’s production requirements – whether for automotive components, industrial parts, or high-mix specialist products.

Conveyorised systems allow for smooth, automated movement of components between key finishing stages such as spray booths, curing ovens, and pre-treatment areas. This approach not only eliminates manual handling but also ensures consistent cycle times and uniform finish quality.

Automated control systems provide real-time data, allowing production managers to optimise throughput, monitor energy consumption, and make continuous improvements.

Unitech’s conveyorised finishing solutions are all UK-manufactured at their Burntwood facility, enabling full control over quality, lead times, and bespoke adaptations. With every installation, safety is prioritised – systems are fully compliant with UK health and safety regulations, and features such as operator guarding, automated lifts, and integrated extraction are standard.

From Consultation to Aftersales: True Turnkey Support

Unitech’s turnkey approach means every project is managed end-to-end by a dedicated team. From the initial consultation, where engineers work closely with clients to understand objectives and operational environments, through to detailed design, manufacturing, and installation.

The company’s project managers oversee every phase, ensuring clear communication, coordinated schedules, and minimal disruption to ongoing operations. Clients benefit from having a single point of contact throughout, streamlining management and reducing risk.

After installation, Unitech’s comprehensive aftersales support covers maintenance, spares, compliance testing, and rapid-response breakdown cover. Extended warranties and regular servicing packages are available to maximise uptime and protect clients’ investment over the long term.

Sustainable, Energy-Efficient Solutions

Energy efficiency is central to Unitech’s offer, with solutions designed to reduce both operational costs and environmental impact. Energy efficient spray booths feature LED lighting, smart airflow control, and programmable modes to minimise energy use during periods of inactivity. Many projects also incorporate heat recovery, advanced filtration, and data-driven process management to ensure sustainable operation.

Unitech’s in-house team works with clients to assess their energy usage and identify opportunities for further savings, supporting both carbon reduction targets and improved cost control. As energy prices and regulatory scrutiny increase, these benefits are more valuable than ever.

Trusted by Industry Leaders

Unitech Machinery’s turnkey finishing solutions are relied upon by leading names such as JCB, Rolls-Royce, Bentley, and Jaguar Land Rover. The company’s proven track record covers sectors including automotive OEM, aerospace, rail, commercial vehicles, and advanced manufacturing. Every system is engineered for reliability, long service life, and full compliance with UK standards.

For businesses looking to modernise, automate, or expand their finishing operations, Unitech offers unmatched expertise and an unwavering commitment to client success.

Find Out More

If your business is seeking ways to increase productivity, lower operational costs, and stay ahead of regulatory requirements, Unitech Machinery’s bespoke surface finishing systems provide a proven path forward. To see how advanced 3D modelling and conveyorised finishing lines could transform your facility, talk to our experts or visit our website for recent case studies and more information.

Frequently Asked Questions

What are turnkey finishing solutions?

Turnkey finishing solutions are comprehensive packages where a single provider manages every stage—from initial consultation and design through to manufacturing, installation, commissioning, and aftercare. For clients, this means one point of contact, reduced project risk, and a fully integrated, ready-to-use system.

How does 3D modelling benefit my project?

Unitech’s 3D modelling service allows you to visualise your entire finishing system before manufacture, identify workflow or space issues early, and avoid costly on-site modifications. This leads to faster project delivery, fewer surprises, and better production efficiency.

What industries does Unitech serve?

Unitech supplies finishing systems to a wide range of industries, including automotive, aerospace, rail, commercial vehicles, general engineering, and specialist manufacturing sectors.

Why choose a conveyorised system?

Conveyorised finishing lines automate the movement of products between process stages, increasing throughput, ensuring consistent quality, and reducing manual labour. They’re ideal for high-volume or complex manufacturing environments.

Is Unitech equipment manufactured in the UK?

Yes, all Unitech Machinery finishing systems are designed and built in their Burntwood, UK facility, ensuring high standards of quality and rapid lead times.

What support is available after installation?

Unitech provides comprehensive aftersales support, including maintenance, parts, compliance testing, and emergency breakdown cover to keep your operation running smoothly.