Energy Saving

Unitech Machinery is dedicated to providing innovative energy-saving solutions that enhance operational efficiency, reduce energy consumption, and support sustainability goals across various industries.

Warm Air Recovery Systems

Our warm air recovery systems capture waste heat from thermal processes, redirecting it back into the production facility.

This reduces energy costs and enhances overall efficiency, making your operations more sustainable.

By utilising residual heat that would otherwise be lost, these systems significantly lower the energy required to maintain optimal working temperatures.

Designed for compatibility with both new and existing equipment, our warm air recovery systems offer flexible integration options.

Industrial LED Lighting

Unitech Machinery provides energy-efficient lighting solutions designed to enhance visibility while significantly reducing energy consumption.

Our advanced LED lighting systems are engineered to provide optimal illumination for various industrial applications, ensuring that workspaces are safe and productive.

By replacing outdated lighting with modern LED options, businesses can achieve substantial energy savings and improve overall operational efficiency.

Our lighting solutions are designed with flexibility in mind, allowing for custom configurations that meet the specific needs of your facility.

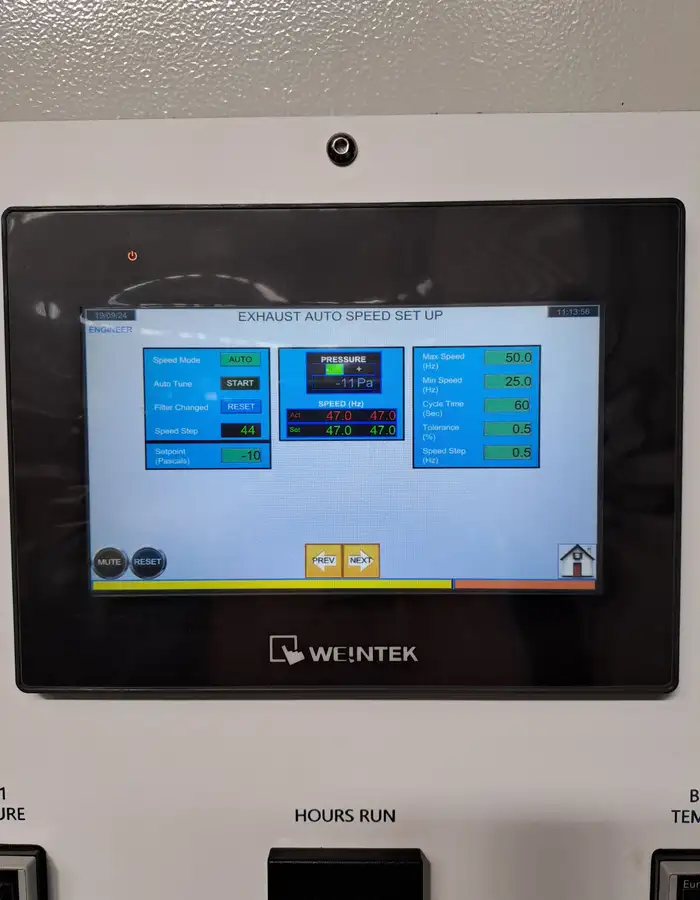

Industrial Control Systems

Unitech Machinery offers advanced control systems designed to optimise the performance of your equipment while minimising energy consumption.

Our control solutions provide precise management of various processes, ensuring that operations run smoothly and efficiently. By integrating intelligent controls, businesses can achieve significant energy savings and enhance overall productivity.

Our control systems are equipped with user-friendly interfaces that allow operators to monitor and adjust settings in real-time.

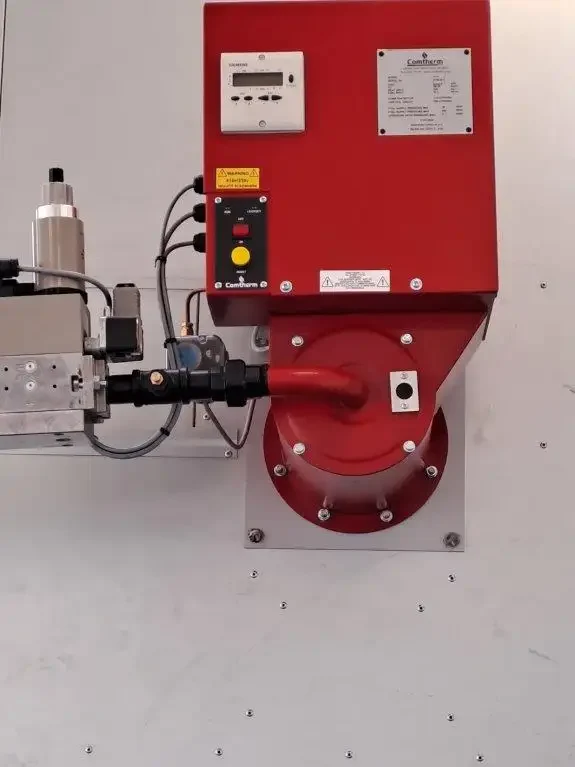

Energy Efficient Burners

Unitech’s energy-efficient burners are engineered to optimise fuel combustion, significantly reducing energy costs while ensuring consistent and reliable heat output for various industrial applications.

These burners are designed to replace outdated systems, providing a modern solution that enhances both performance and efficiency.

Our burners feature advanced technology that maximises fuel efficiency, allowing businesses to lower their operational costs while maintaining high-quality output

Flash Off

Our flash off systems enhance the drying process of waterborne paints, ensuring quick evaporation of moisture.

This efficiency not only speeds up production but also reduces energy consumption, making them an essential component of modern manufacturing processes.

By creating an optimal environment for drying, these systems help prevent defects in paint finishes, ensuring high-quality results.

Energy Efficient Paint Finishing Systems & Burners

Reducing energy consumption is the single biggest priority for modern paint shops. As a leading UK manufacturer, Unitech Machinery specialises in energy efficient spray booth systems and process heating solutions designed to slash operational costs and reduce your carbon footprint. By upgrading to our high-efficiency burners and smart control systems, manufacturers can typically reduce fuel usage by 30-40% while improving process stability.

Our engineering team can audit your existing plant and recommend retro-fit upgrades or design completely new energy-saving lines. We focus on three key areas: intelligent heating, waste heat recovery, and precision control.

Core Energy Saving Technologies

- High-Efficiency Gas Burners: We install fully modulating burners that precisely match heat output to demand, eliminating the “on-off” spikes that waste fuel.

- Warm Air Recovery Systems: Our heat exchangers recapture waste heat from stoving ovens and use it to pre-heat incoming air, drastically reducing boiler load.

- Flash-Off Tunnels: Dedicated controlled evaporation zones remove solvents efficiently, reducing the time and energy required in the high-temperature curing oven.

- Industrial LED Lighting: Upgrade to ATEX-compliant LED systems that deliver better colour rendering while cutting electricity usage by 60% compared to fluorescent tubes.

- Smart Control Systems: Automated standby modes, variable speed drives (VSDs), and intelligent airflow management ensure you only use energy when product is actually being processed.

ROI & Sustainability

With rising industrial energy prices, an inefficient spray booth or oven is a financial liability. Our UK-made energy saving solutions offer a rapid Return on Investment (ROI), often paying for themselves within 12-18 months through direct fuel savings. Beyond cost, upgrading your equipment helps your business meet environmental targets and ISO 14001 sustainability standards.

Government Incentives: Full Expensing & Made Smarter

Investing in energy-efficient machinery now qualifies for major UK government incentives. Under Full Expensing, you can claim 100% first-year tax relief on qualifying plant and machinery.

Additionally, the Made Smarter Adoption Programme offers grant funding for digital technologies like our Smart Control Systems, further reducing your initial outlay.

Contact us for a free energy audit of your paint facility.

Elevate Your Production with Unitech Machinery

Unitech Machinery has over 50 years of experience in paint finishing equipment and custom solutions to elevate your production with cutting-edge technology. CONTACT US now to boost your business efficiency and quality.