Spray Test Page

Spray Test Page

Spray Test Page

Our flash off systems enhance the drying process of waterborne paints, ensuring quick evaporation of moisture.

This efficiency not only speeds up production but also reduces energy consumption, making them an essential component of modern manufacturing processes.

By creating an optimal environment for drying, these systems help prevent defects in paint finishes, ensuring high-quality results.

Spray Test Page

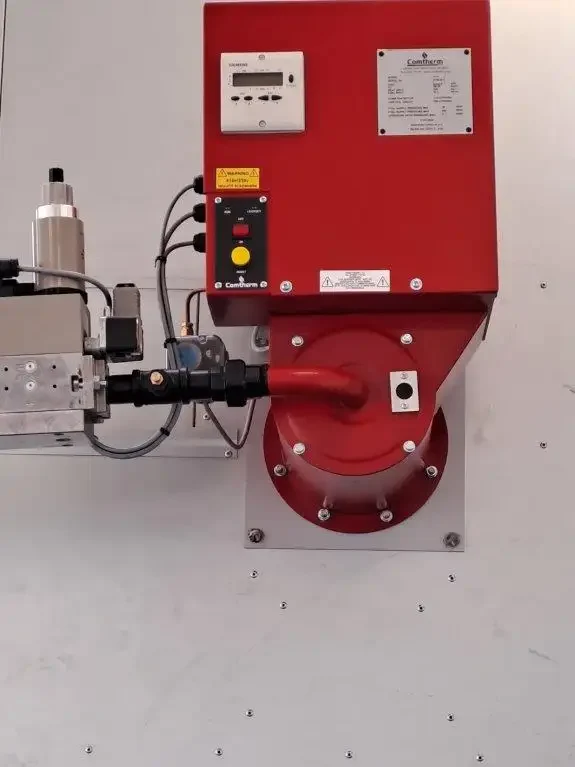

Unitech’s energy-efficient burners are engineered to optimise fuel combustion, significantly reducing energy costs while ensuring consistent and reliable heat output for various industrial applications.

These burners are designed to replace outdated systems, providing a modern solution that enhances both performance and efficiency.

Our burners feature advanced technology that maximises fuel efficiency, allowing businesses to lower their operational costs while maintaining high-quality output

Spray Test Page

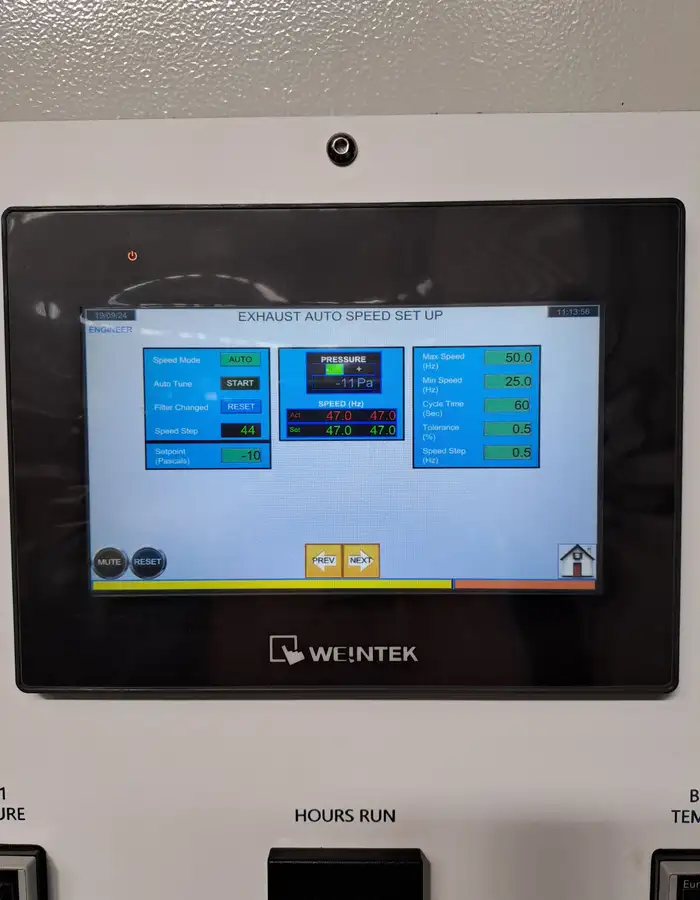

Unitech Machinery offers advanced control systems designed to optimise the performance of your equipment while minimising energy consumption.

Our control solutions provide precise management of various processes, ensuring that operations run smoothly and efficiently. By integrating intelligent controls, businesses can achieve significant energy savings and enhance overall productivity.

Our control systems are equipped with user-friendly interfaces that allow operators to monitor and adjust settings in real-time.

Spray Test Page

Unitech Machinery provides energy-efficient lighting solutions designed to enhance visibility while significantly reducing energy consumption.

Our advanced LED lighting systems are engineered to provide optimal illumination for various industrial applications, ensuring that workspaces are safe and productive.

By replacing outdated lighting with modern LED options, businesses can achieve substantial energy savings and improve overall operational efficiency.

Our lighting solutions are designed with flexibility in mind, allowing for custom configurations that meet the specific needs of your facility.

Spray Test Page

Our warm air recovery systems capture waste heat from thermal processes, redirecting it back into the production facility.

This reduces energy costs and enhances overall efficiency, making your operations more sustainable.

By utilising residual heat that would otherwise be lost, these systems significantly lower the energy required to maintain optimal working temperatures.

Designed for compatibility with both new and existing equipment, our warm air recovery systems offer flexible integration options.

Spray Test Page

Unitech Machinery offers a range of industrial ovens designed to meet the needs of modern manufacturing and production processes.

Our ovens are durable, energy-efficient, and customised to suit your specific requirements.

With options for various sizes, temperature ranges, and airflow systems, they ensure precise and consistent performance for applications like curing, drying, and heat treatment.

Whether you need a standard model or a bespoke solution, our industrial ovens are built to enhance your operations and deliver reliable, high-quality results.

Spray Test Page

Spray Test Page

Unitech’s acoustic enclosures are engineered to provide superior sound insulation, making them ideal for isolating noisy machinery and creating quiet zones within bustling industrial environments.

Constructed from high-performance soundproofing materials, these enclosures effectively block sound transmission, ensuring that your workforce is protected from harmful noise exposure.

Our enclosures are fully customisable, allowing you to choose dimensions, configurations, and features that best suit your operational needs.

Whether you require ventilation systems, access doors, or viewing panels, our design team will work closely with you to create a solution that integrates seamlessly into your existing setup while maximising sound reduction.

Spray Test Page

Unitech’s acoustic walls offer an effective solution for soundproofing within your facility, providing a barrier against noise that can disrupt operations and affect employee well-being.

These walls are designed to significantly reduce sound transmission, making them ideal for separating noisy areas from quieter workspaces, thus enhancing overall workplace comfort.

Our acoustic walls are highly versatile and can be tailored to fit various configurations and sizes, ensuring that they meet the unique demands of your facility.

With options for integrated doors and windows, our walls maintain functionality while providing the necessary sound insulation. This flexibility allows for easy integration into existing structures without extensive renovations.

Spray Test Page

Unitech Machinery supplies heat treatment ovens designed to meet the precise requirements of modern manufacturing processes.

Our ovens are built for reliability, energy efficiency, and consistent performance, with options tailored to suit your specific heat treatment needs.

Available in a range of sizes and configurations, they are ideal for applications such as annealing, tempering, and stress relieving, ensuring accurate and repeatable results.

Whether you require a standard model or a custom-built solution, Unitech Machinery’s heat treatment ovens are designed to integrate seamlessly into your operations and deliver dependable performance.

Spray Test Page

Spray Test Page

Unitech Machinery designs and manufactures box and curing ovens to meet the specific needs of industries such as automotive, aerospace, and manufacturing.

These ovens are engineered for reliability and efficiency, offering precise temperature control and consistent performance for processes like powder coating, paint curing, and heat treatment.

With options for custom sizes, temperature ranges, and control systems, our ovens are built to integrate seamlessly into your production line.

Whether you need a standard model or a bespoke solution, Unitech’s box and curing ovens are designed to optimise your workflow and deliver dependable, high-quality results.

Spray Test Page

Spray Test Page

Unitech Machinery’s dry off ovens are designed to efficiently remove moisture from components after pre-treatment processes, ensuring they are ready for subsequent finishing stages.

Built with precision and reliability in mind, these ovens provide consistent airflow and temperature control to achieve rapid and uniform drying.

With options for custom sizes, energy-efficient heating systems, and advanced control features, our dry off ovens are tailored to meet the specific needs of industries such as automotive, aerospace, and general manufacturing.

Whether you require a standalone unit or integration into a larger production line, Unitech’s dry off ovens deliver dependable performance and seamless operation.

Spray Test Page

Spray Test Page

Unitech Machinery’s powder cure ovens are designed to deliver precise and consistent results for powder coating applications.

These ovens ensure the powder coating bonds effectively to the surface, enhancing durability and finish quality.

With advanced temperature control, energy-efficient heating systems, and customisable configurations, our powder cure ovens are ideal for industries such as automotive, aerospace, and manufacturing.

Whether you need a standalone unit or integration into a larger system, Unitech’s powder cure ovens provide reliable performance tailored to your production needs.

Spray Test Page

Unitech Machinery provides a selection of automotive spray booths designed to meet the demands of busy bodyshops and workshops.

Built in the UK, our spray booths are reliable, efficient, and tailored to suit your specific requirements.

With options for different airflow and extraction systems, they help improve paint application while keeping energy costs low.

Whether you need a standard model or a custom solution, our automotive spray booths are built to support your business and deliver consistent, high-quality results.

Spray Test Page

Spray Test Page

Our industrial booths are tailored to suit your specific processes, whether you’re working with large equipment, complex components, or high-volume production.

With options for different airflow systems and custom configurations, our industrial spray booths ensure efficient paint application, a safe working environment, and compliance with industry standards.

Whatever your requirements, we provide reliable solutions to support your business.

Spray Test Page

Built in the UK, these booths use advanced filtration systems to capture overspray and maintain a clean working environment.

Available in both open-fronted and enclosed designs, they are tailored to suit your specific needs while meeting safety and environmental standards.

Whether you’re working with small components or larger items, our dry filter spray booths provide a practical and cost-effective solution for your business.

Spray Test Page

These Water Wash booths use a water scrubbing system to efficiently capture paint overspray, dust, and fumes, ensuring effective air filtration.

They are available in both open-fronted and enclosed designs, with options for pumped or pumpless operation. Ideal for applications such as automotive, aerospace, and marine, our water wash spray booths offer a reliable and low-maintenance solution tailored to your specific needs.

Spray Test Page

These booths are engineered to provide excellent overspray capture and ensure a clean working environment, making them ideal for industries such as automotive, manufacturing, and aerospace.

With a range of sizes and configurations available, our powder coat spray booths can be tailored to suit your specific requirements, helping to optimise your coating processes and maintain high-quality finishes.